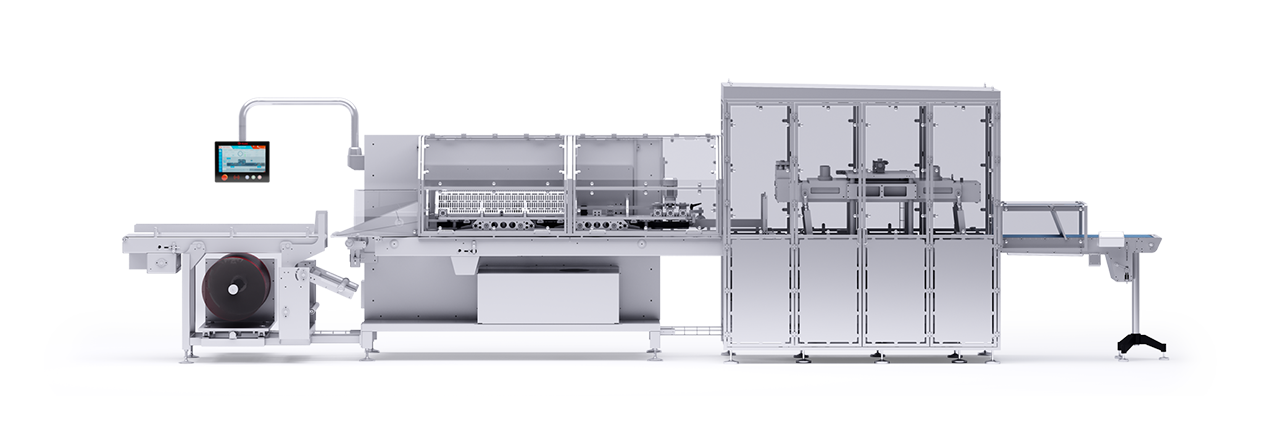

OMEGA 800

The process may be divided into two main stages: packaging and vacuum.

In the first phase, the film is tubular formed and longitudinally sealed around the product.

In the second phase, the vacuum and the transversal sealing take place. At the same time, one side is sealed outside the chamber and one side is sealed into the chamber.

Changeovers from one package size or shape to another do not require any changes to the line; therefore the machine can run continuously, resulting in a significant reduction of cost and time while increasing productivity.

Flexible

ideal for different size products and irregular shapes

Rock-solid

stainless steel frame & components

Efficient

0% of scrap, use of 100% material

User friendly

Which allows an easier access to all machine functions, by simplifying the settings, the machine activation and system check.

Compatible

with automatic product loading